Products

Chip Handling Systems

Steel Belt conveyors

Hinged steel belt conveyor is best suited for low coolant content and bushy and broken chips. Pitch sizes of 2.5 Inches (63 mm), 4 Inches (100 mm) and 6 inches (150 mm) are typically used for chip handling, depending on expected load. Special designs incorporating dimples, perforations and reinforcements are available to suit more demanding applications.

Enquire Now

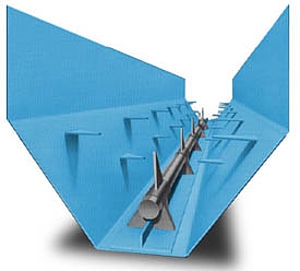

Push Bar Conveyors

The Push Bar Conveyor is the ideal solution where large quantities of bushy chips are carried over long distances. Large coolant flow can easily be handled; even small, cast-iron chips can be transported in this conveyor. Because of its reliability, high capacity and long conveying length of upto 170 meters this conveyor is widely used in the automotive and bearing manufacturing Industries. Lately the push bar conveyor has found use in the state-of-the-art F.M.S. plants.

Advantages:

- Solves conventional problems such as wearing of pusher roads

- Vastly increases the conveying distance at very low costs; the longer the conveyor the more economical is the operation. Modular design facilitates easy extension of the conveyor

- The construction features wear resistant parts for application involving abrasive materials, to give long life to the equipment

Drag Link Conveyor

Drag Link Conveyors are best suited for handling small, powder chips over long distance. Typically cast iron, brass or aluminium chips from machining operations that generate small or powder chips are well conveyed by this conveyor.

Enquire Now

Products

Chip processing Systems

Chip Shredder & Crusher

Benefits of Chip Crushing:

- Lowers the volume of the chips to as much as 15 percent of the original, thereby reducing transportation costs drastically.

- Reduces size of the swarf for subsequent centrifugation, briquetting or over floor pumping. Also helps in recovery of coolant from chips.

- Makes it convenient for steel melting shops to increase productivity of their furnaces

Chip Centrifuge - VBU

The present day machining practices make use of expensive oils which, without recovery, would result in a substantial increase in the cost factor, not to mention the increased threat to the environment. The VBU helps recover this expensive oil which can be reused either directly or after filtration depending on the machining activity. The relatively dry chips produced as a result of centrifuging fetch a much higher value during sale. Various sizes of VBUs are available to handle upto 5 tones per hour of processing capacity.

Advantages:

- Excellent returns on investment, especially for neat oil applications.

- Automatic and continuous operation.

- Perfect way to recover precious residual oil from wet chips.

- Adjustable wringer speed to fit individual requirements.

- Easy to maintain & low running cost.

- Superb de-oiling

Integrated Chip Processing

The Reclamet-3000 is turnkey solution with a screw feeder, shredder, tramp material separator and centrifuge. The centrifuge is designed to enable pneumatic conveying of chips. Though compact in size, the Reclamet® can handle relatively high volumes of chips and coolant and is well suited for centralized applications. The Reclamet® comes with an option of overhead storage silos that facilitate easy and automated discharge of chips into trucks of containers. This system can be used for both emulsion and neat cutting oil applications.

Advantages:

- Ensures recovery of over 95% of cutting oils from metal chips

- Expensive coolant reclaimed resulting in enormous cost savings

- Compact, efficient, versatile and dependable system

- Proven and successfully installed in many countries

Chip Briquetting

Chip compactor is used to compact waste metal scrap produced from metal cutting operations like milling, turning, boring etc., The compactor uses force to press the scrap into briquettes of different sizes based on the applications. The force used to achieve this enables the briquettes to be highly dense, typically more than half the density of the original metal. Almost any type of material can be processed in this Chip Compactor.

Enquire Now