Products

Centralized Filtration

Miven Mayfran designs and builds tailor-made filtration plants for coolant and chip handing. Technology driven products backed by decades of experience, strong project management skills, and range of coolant filtration technologies to choose from, including gravity, pressure or vacuum filters, make Miven Mayfran the preferred partner of industry majors. These quality products from the Miven Mayfran stable, prolong coolant life thereby bringing down the cost of coolant management significantly.

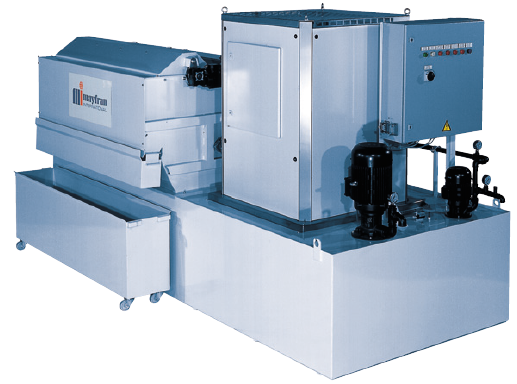

Vacuum Band Filtration

It works on the principle of suction of coolant through the filter media. Once a filter cake is formed on the surface of the media, a pre-set vacuum is created which triggers the indexing of the filter media. Advanced engineering and manufacturing techniques ensure that the vacuum seals are maintained perfectly.

Advantages:

- Delivery pumps are used to create vacuum resulting in energy savings.

- Can handle a wide range of chips.

- Consumes far less media compared to gravity filters.

Perma-flow Filtration

It has proven its efficiency, time and again-due to its reliability, flexibility installation options, as well as low operating costs for filtering coolant. The configuration of the Perma-Flow vacuum filter offers higher percentage purity without the use of filter consumables.

Advantages:

- Continuous, fully automated operation

- Compact and modular

- No disposal costs for filter media

- Additional filter drums can be easily retrofitted

- Maximum flexibility

- Filter elements can be inspected without emptying the reservoir

Pressure Filtration

Pressure belt filter offers an efficient and effective way to reduce your overall coolant costs in grinding and turning applications. Here filtration takes place when coolant mixed with chips is passed through a media under pressure. Pressure bed filters deliver very good filtration quality for high flow rates. Miven Mayfran’s pressure filtration technology offers a reliable way to improve system uptime. Custom-engineered and fully automatic, it is an ideal solution for a variety of processes and materials.

With proper media selection, you can expect up to a 99% efficiency rating for applications, including machining, grinding, drilling, honing, polishing and washing. Other features include:

- Capacity up to 5,000 gpm

- Able to achieve fluid clarity levels to less than 10 microns using a filter aid (pre-coat)

- Effective filtration for fine and short chip types

- Outstanding drying of filter cake

Rotary Belt Filtration

Rotary Belt Filter is a permanent media filter that brings the advantage of reduced operating cost. This low maintenance filter works on simple hydrostatic principle.

RBFs can be applied for machining operations including finish operations such as grinding. Suitable for single machine as well as centralized applications.

Enquire NowPre-coat Filtration

Pre-coat filtration is applied for filtration of pure oil in honing and reaming operations for by-pass operations in pure oil applications. This filter provides very high class filtration.

Advantages:

- Very High Grade Filtration

- Effective for honing and other super finishing operations.

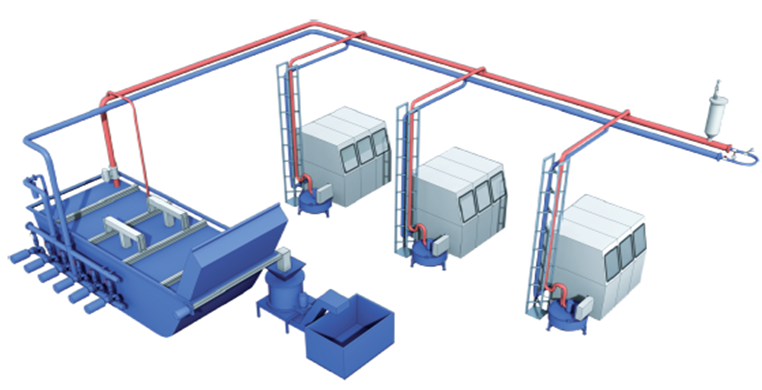

Viavent System

Viavent® is an automatic overhead closed loop chip and coolant transportation system. Chips and coolant are pumped through an overhead piping system and flushed into a central filter unit. The filtered coolant is then re-circulated back to the machines. The closed loop Viavent piping system maintains optimal coolant quality and minimizes evaporation. The Piping structure is so designed that the entire mixture of cups and coolant is flushed into the filter and there is absolutely no sedimentation of chips in the pipes.

Main Features:

- Pumps both coolant and chips automatically from machine tools.

- Digests larger chips than conventional pump back systems.

- Ensire no clogging or sedimentation of chips in the piping.

- Reduces energy costs (Compared to Conventional systems)

Advantages:

- Flexible Shop layout

- Less Risk of pollution

- Reduced operating cost

- Easy access for maintenance

- Improved safety features.